Case Study: When Flexibility and Quick Prototyping Are Mission Critical

Client

GP Reeves – a global provider of engineered dispensing systems and solutions

Problem

GP Reeves needed to outsource a stand that would support their technology and hold bulk sanitizer solution, both quickly and for the right price point.

Solution

OMT-Veyhl designed a solution in record time that met the requirements and cut costs.

Summary

When orders are placed before a product is even developed, flexibility and quick prototyping capabilities are mission critical. Learn how GP Reeves Inc. partnered with OMT-Veyhl to fulfill an exploding market need amidst a global pandemic.

Introduction

For more than 45 years, GP Reeves Inc. has been a global provider of engineered dispensing systems and solutions for manufacturing. So, when the world entered a global pandemic, they knew they could utilize their existing technology to fulfill a major shortage: hand sanitizing stations.

“The market was exploding before our eyes. We started with orders, but we still needed to figure out how to make the product,” said Kevin Reeves, President of GP Reeves.

The company needed to outsource a stand that would support their technology and hold bulk sanitizer solution, both quickly and for the right price point. As OMT-Veyhl’s supplier of grease dispensers, GP Reeves was in the OMTV facility and decided that this trusted partner had the ability to create exactly what was needed.

“One of the biggest factors for choosing OMT-Veyhl, in addition to the quick prototyping capabilities, was the security we had. We knew that when we ramped up orders, they would be able to keep up with the high volume. They were committed to do this with us.”

The stand would be a new product for OMT-Veyhl, stepping aside from their more known office furniture products, such as height adjustable table bases, and the OMTV team embraced the opportunity.

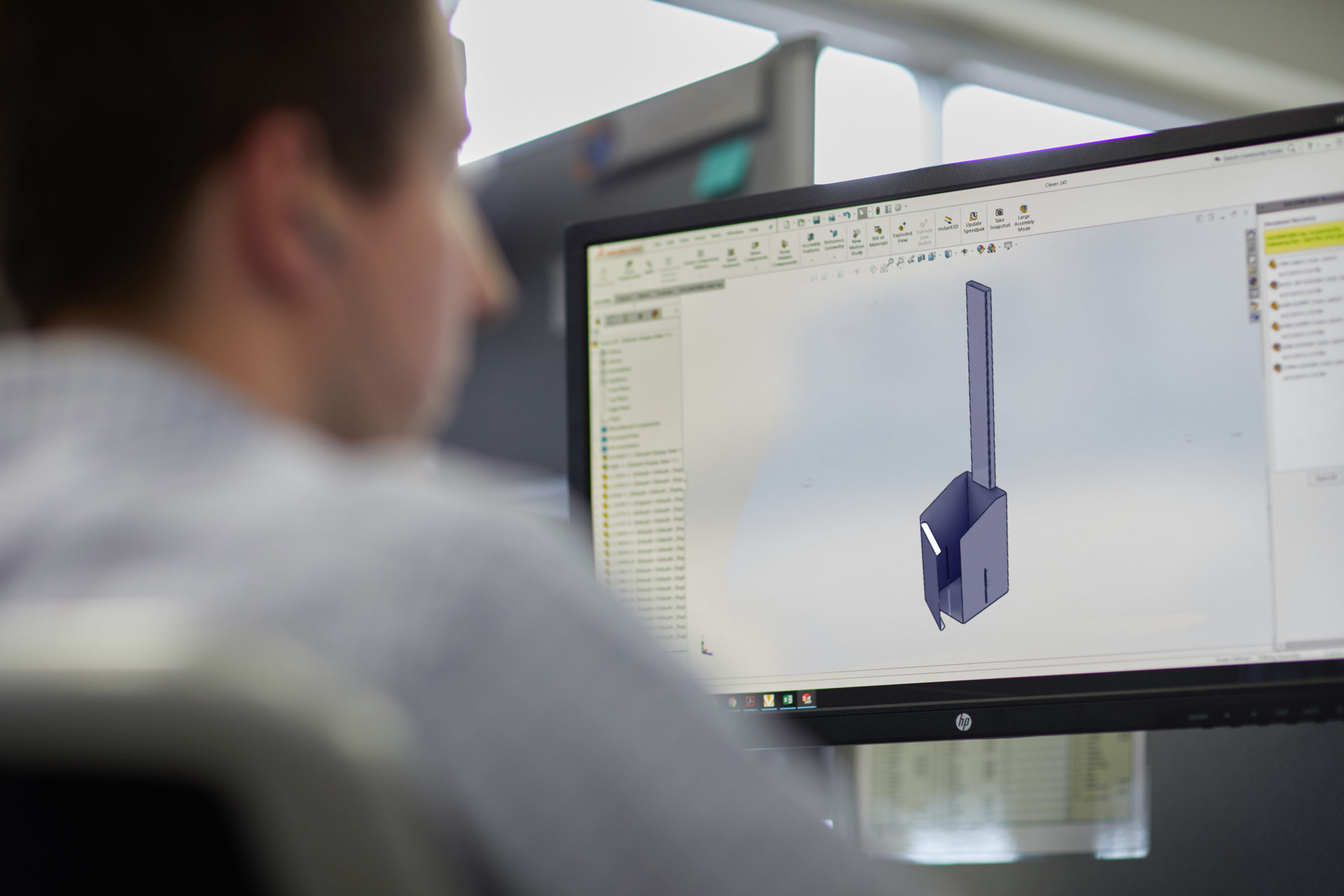

Designing in Record Time

Tasked with a goal for an initial 500 units as soon as possible, OMT-Veyhl responded with a rapid turnaround, from sketch to original prototype in 4 days. But OMT-Veyhl did not cut corners to simply create the fastest option, instead they also engineered the product with a new design to save the customer capital.

Tasked with a goal for an initial 500 units as soon as possible, OMT-Veyhl responded with a rapid turnaround, from sketch to original prototype in 4 days. But OMT-Veyhl did not cut corners to simply create the fastest option, instead they also engineered the product with a new design to save the customer capital.

The original sketch brought to OMT-Veyhl was a single unit, but in order to create access to the sanitizing solution bottle for refills, the team was able to design a version that used no additional hardware and utilized sheet metal as a door – both meeting requirements and cutting costs.

“OMT-Veyhl did a good job working with us. If we had an idea that wouldn’t be user friendly or would be too expensive, they were willing to say that when it needed to be said to direct us and lead us down a better path. They are innovative and willing to design quickly. The whole process took 2 weeks versus the typical 6 months.”

Benefits of Flexibility

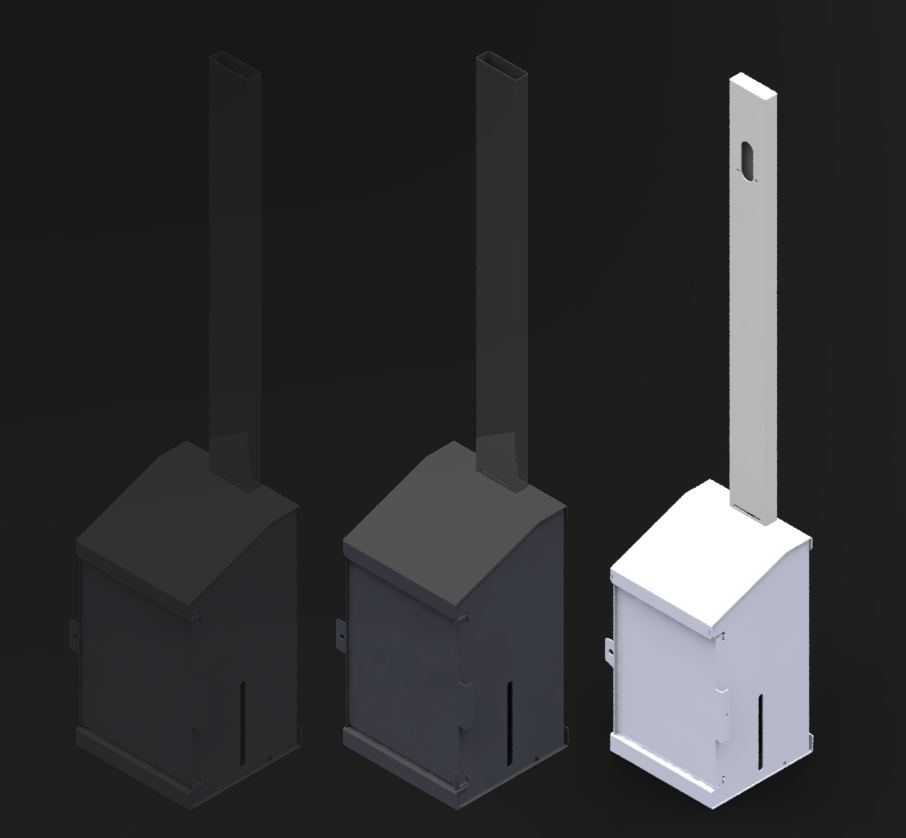

After weighing the options of other manufacturers, GP Reeves was also impressed by OMT-Veyhl’s powder coating capabilities. For the same price, the products could be painted with a thick finish to prevent chipping and scratching. OMT-Veyhl’s 200+ color options were a bonus, and GP Reeves was able to stray from the original single-color plan.

“Not everything is going to work perfectly when you do a speed to market product – that’s just the reality of it – but OMT-Veyhl continued to work through that and make continuous micro improvements to the process and products. These things normally drive a supply chain nuts, but OMT-Veyhl was flexible, replacing typical design reviews with production reviews to continue to solve how we can make the next batch even better.”

As a result of a successful partnership, GP Reeves continued to work with OMT-Veyhl to create three additional versions of the stand to fit different needs and sizes, and OMT-Veyhl’s adaptability has allowed for revision changes to be made while simultaneously producing production quantities.

“One of the biggest factors for choosing OMT-Veyhl, in addition to the quick prototyping capabilities, was the security we had. We knew that when we ramped up orders, they would be able to keep up with the high volume. They were committed to do this with us.”