Start to Finish Metalworking

Every product we manufacture is made to the highest quality standards, incorporating premium materials, LEAN manufacturing processes, and the latest innovations in automated manufacturing equipment. Our lead times and quality standards are the envy of the industry. Contact our team to schedule a tour of our facility to see our equipment and processes in person!

Manufacturing Technology

We are aggressive in adopting the latest manufacturing technology to empower our skilled tradespeople to provide superior quality and the shortest possible delivery times in the contract furniture industry today. Computer-driven laser-cutters cut parts quickly to very high tolerances. Our brake presses provide for rapid bending and forming. Robotic laser welding rapidly creates assemblies with a very high degree of fit and finish, less material waste, and little to no burn through. It all contributes to the highest standards of manufacturing quality and efficiency.

Powder Coating

At OMT-Veyhl, our favorite color is yours. With more than 150 standard colors and the ability to customize a finish to suit your requirements, we offer color options that are unsurpassed in the industry. See our Color Quick Reference to get started. Two separate powder coating lines are available to accommodate your needs for everything from small-run customization to large-order production.

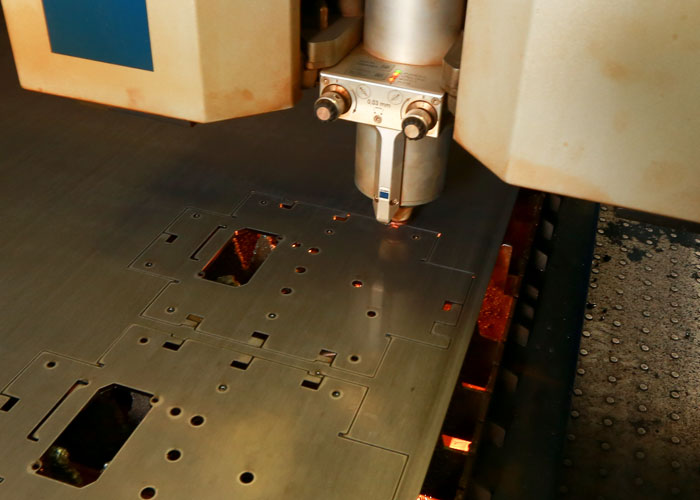

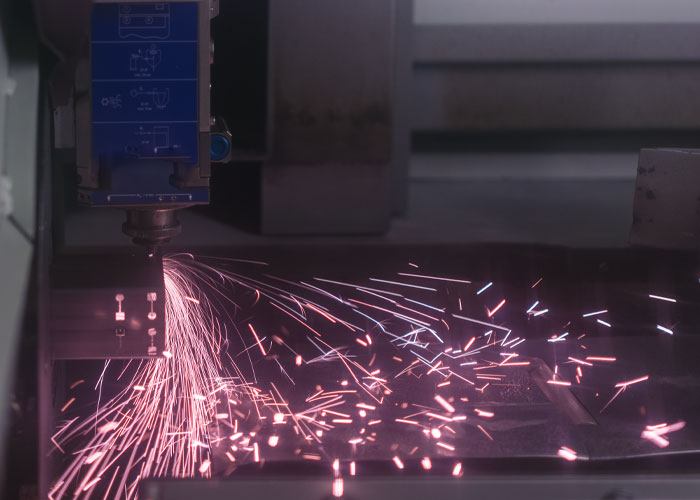

Laser Cutting: Sheet Metal

Computer-driven laser-cutters cut parts quickly to very high tolerances. Our manufacturing facility is home to both Carbon Dioxide and Nitrogen lasers. A team of skilled programmers work hard in this step of the fabrication process to ensure the raw material is utilized in an efficient and sustainable way.

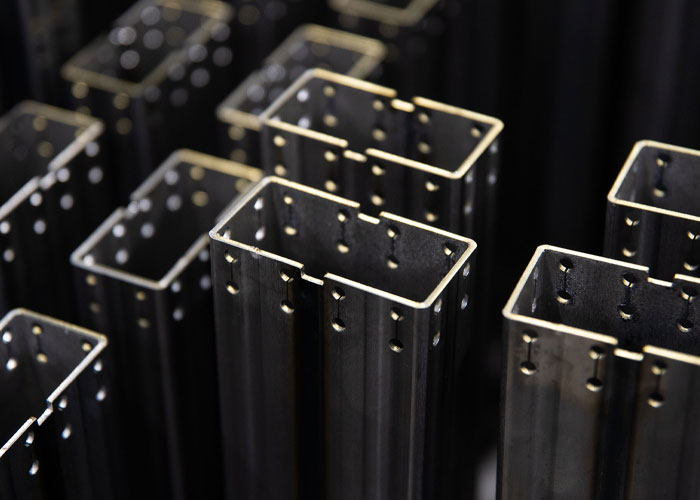

Laser Cutting: Tubes

In addition to sheet metal, OMT-Veyhl also specializes in tube metal. OMT-Veyhl’s five in-house tube lasers create clean and precise cuts with smooth edges. These automated machines support high-volume production with top-level accuracy and consistency.

Bending

After the sheet metal has been cut into its proper shapes, the skilled technicians at OMT-Veyhl complete a variety of bends on our brake presses. OMT-Veyhl currently has 5 different brake presses in the facility.

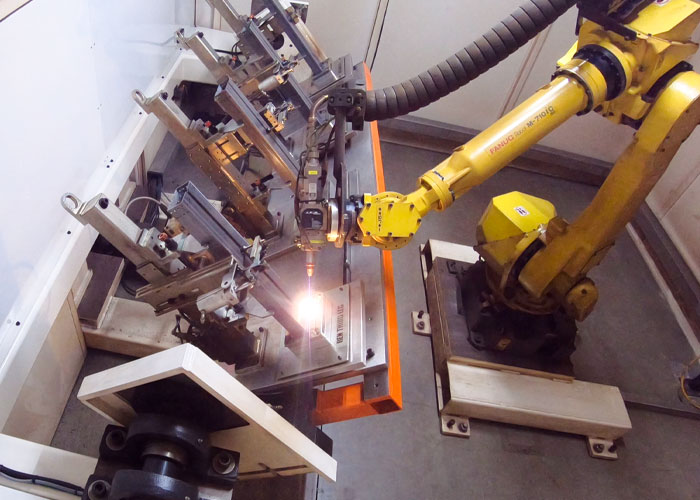

Laser Weld

Robotic laser welding rapidly creates assemblies with a very high degree of fit and finish, less material wasted, and little to no burn through.

Manual Weld

Welding is the final step in the fabrication department before a product is ready to be painted. OMT-Veyhl utilizes both MIG and TIG welding with systems in place to ensure consistent welds with a high degree of fit and finish.

Automated Powder Coating

The newest of OMT-Veyhl’s two powder coat lines is fully automated and engineered for efficiency and speed, enabling single-rack changeovers. Its waste reduction technology also allows us to operate with minimal overspray.

Manual Powder Coat

Our manual powder coat line is run by skilled technicians who can change colors in 30 seconds on average, and as much as 180 color changes in a day. OMT-Veyhl offers more than 200 colors to create a curated product offering for your customers.