Case Study: Putting Customer Satisfaction First

Client

New York-based furniture manufacturer

Problem

The customer needed a moveable desk solution that met lower-than-average height requirements.

Solution

OMT-Veyhl re-engineered a leg design to meet the required height limit and included casters for mobility.

Summary

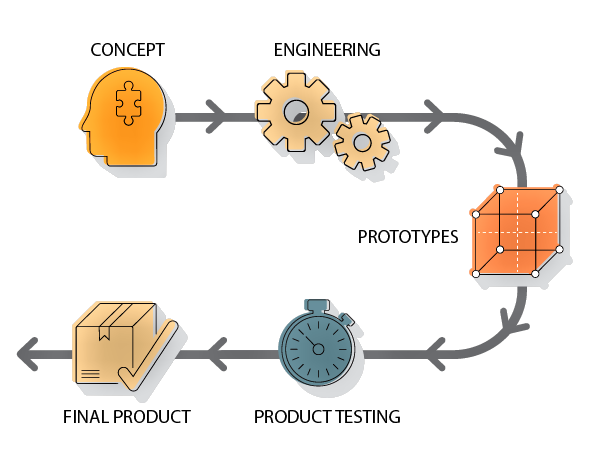

Manufacturers’ primary goal is to deliver a product that meets the specifications and time parameters of their clients. So, when they need to bring in a third party to create a custom product, they rely on a partner who equally values a commitment to delivering as expected. Learn how a New York–based furniture manufacturer focused on ergonomics partnered with OMT-Veyhl to develop a custom healthcare solution that not only met ANSI/BIFMA standards but also was produced on time and to budget.

Introduction

For more than 30 years, a New York–based furniture manufacturer has been known as a pioneer of office ergonomics. So, when one of the country’s largest not-for-profit healthcare providers began looking for a height-adjustable table for its mental and behavioral health centers, the choice was an easy one. The provider specifically was looking to address the ANSI/BIFMA requirement that all adjustable-height tables can reach a seated position of 22 inches—a standard much lower than the average adjustable-height table on the market. These tables were to be used for healthcare providers to interact with patients in a modular therapy room, hence the need to adjust based on task.

A Consultative Approach

The manufacturer decided to turn to an outside source to design a solution. Having worked with OMT-Veyhl in the past, the company was its first choice. Originally, the manufacturer considered a table from OMT-Veyhl’s BOLD line, but because the table was designed with casters that add 2 inches of height, the table did not meet the 22-inch criterion. It became clear that a custom solution was necessary.

The manufacturer’s national sales director remembered the initial project call with OMT-Veyhl well. “From a client perspective, we simply needed to solve a problem. We didn’t need something overengineered or overcomplicated. We needed clean, polished, and functional. With many other manufacturers, they overcomplicate the process, dragging out the design time, resulting in missed deadlines. Yet with OMT-Veyhl, they simply get it. They listened to our needs, and within a week we had a drawing and within two weeks we had a prototype. What’s more, the team worked with us on pricing to determine ways to design a solution that functioned and was within our budget.”

Internal Processes Allows For a Timely Approach

OMT-Veyhl designed a leg that included the casters on the outside of the structure, allowing the table to reach the lowest limit, which was 22 inches. The national

OMT-Veyhl designed a leg that included the casters on the outside of the structure, allowing the table to reach the lowest limit, which was 22 inches. The national

sales director shared that during the process there was one rendition where the foot was too large for the client. “OMT-Veyhl listened to the feedback and delivered a revised project in a timely fashion.”

With internal vertical integration, OMT-Veyhl is able to provide custom-engineered solutions quickly and more cost effectively than its competitors. “We recognize that one of the biggest values we receive in working with OMT-Veyhl is its internal processes,” recalled the national sales director. “The company’s vertical integration allows us access to the design studio and engineering team instead of having to outsource different parts of the puzzle.”

Going the Extra Mile

OMT-Veyhl provided the customer service the manufacturer needed to get the job done, freeing it to focus on its core efficiencies. “If you think of the traditional OEM-brand relationship, the manufacturer will ship to the client and then the client owns the product,” said the national sales director. “For us, we needed a company to do the heavy lifting for us. When working with OMT-Veyhl, we sell a solution, they do the rest.”

What’s more, OMT-Veyhl’s sales staff, comprised of engineers, flew out to meet with the client as an extension of the manufacturer’s team. The national sales director added, “OMT-Veyhl engineers are naturally curious and willing to put in the extra work to get a job done right the first time. When timelines are tight, this nontraditional step is simply invaluable to our brand reputation.”

With other manufacturers, they overcomplicate the process, dragging out the design time, resulting in missed deadlines. Yet with OMT-Veyhl, they simply get it.