We Help Contract Furniture OEMs Make It Happen.

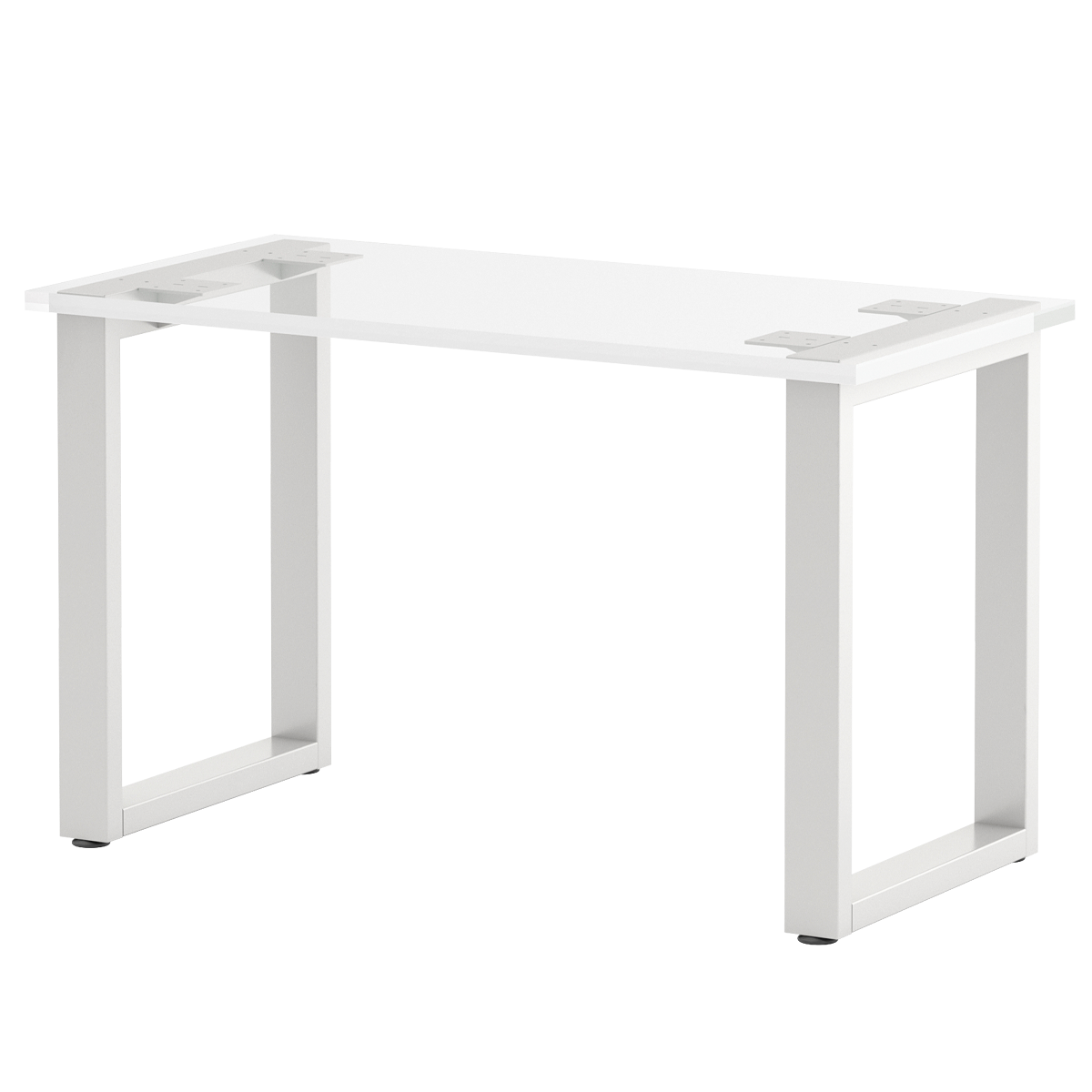

UNIQUE & PRACTICAL CUSTOM OFFICE FURNITURE

Shortest Lead Times in the Industry

Take a Tour

To See More of our State-of-the-Art Facility, Schedule a Tour Today.

Set Up a Visit or Call (616) 738-6688

Sign up for our news feed.

The Hidden Costs of Globalization Aren’t So Hidden Anymore.

We understand you need to be efficient with both marginal costs and capital. Like most other OEMs, you likely moved some or all of your supply chain offshore. With the promise of low per-piece prices, who could blame you? The reality, however, hasn’t been the panacea you were promised. You confront…- High minimum order quantities that cause you to carry excess inventory

- Unpredictable quality control and limited color selections

- Customs delays that snarl your supply chain when you can least afford it

- Geopolitical risks like tariffs, political instability, and trade wars

- Difficult-to-manage suppliers that subcontract to factories you haven’t approved

- Complex order fulfillment that frequently requires mistake-prone re-skidding, warehousing, shipping, and high labor costs

At OMT-Vehyl, We Deliver What We Promise

Integrated Manufacturing Is More Reliable

Tightly integrated and highly automated, at OMT-Veyhl, we take responsibility to meet and exceed all customer expectations.

Starting with steel plate and tube sourced from within a hundred miles of our factory through to final labels and packaging, we have in-sourced and mastered every skill, technology, and process required to deliver the highest quality parts and assemblies.

It’s all a reflection of how seriously we take our obligation to our customers. We’re able to deliver an eight-day turnaround on most orders and near-zero minimum order quantities because we have full control of every aspect of production.

Better By Design. (Automatically.)

Best-in-Class Manufacturing for the

Contract Furniture Industry

Highly automated and computer-driven, we operate a LEAN,

near-zero-defect, rapid changeover manufacturing process featuring:

- Precision laser cutting

- Robotic laser welding

- Computer-vision quality control

- Numerous fixtures and go/no-go gauges

- Automated powder coating

- Automated material handling

- And much more

It all contributes to less waste, fewer defects, better fit and finish,

and ultimately a more economical product. It’s a difference you’ll

appreciate with every part you receive.

Recent Comments