Case Study: The Magic of In-House Capabilities Paired with Customer Communication

Client

Leading medical device company

Problem

A global pandemic caused the desperate and immediate need of more hospital beds.

Solution

OMT-Veyhl’s wide variety of in-house capabilites partnered with strong communication filled the need for speed-to-market manufacturing.

Summary

When a world-wide pandemic led to an unprecedented high demand for patient platforms, the right manufacturers and ease of partnerships were vital. See how OMT-Veyhl’s capabilities and speed made it happen for this leading medical device company.

Introduction

Due to a spike in COVID-19 cases across the world, hospitals, including the makeshift field hospitals, quickly found they did not have enough beds to hold all of the patients in need. Thankfully, one of the world’s leading medical device companies stepped up to the plate to provide for this unprecedented high demand.

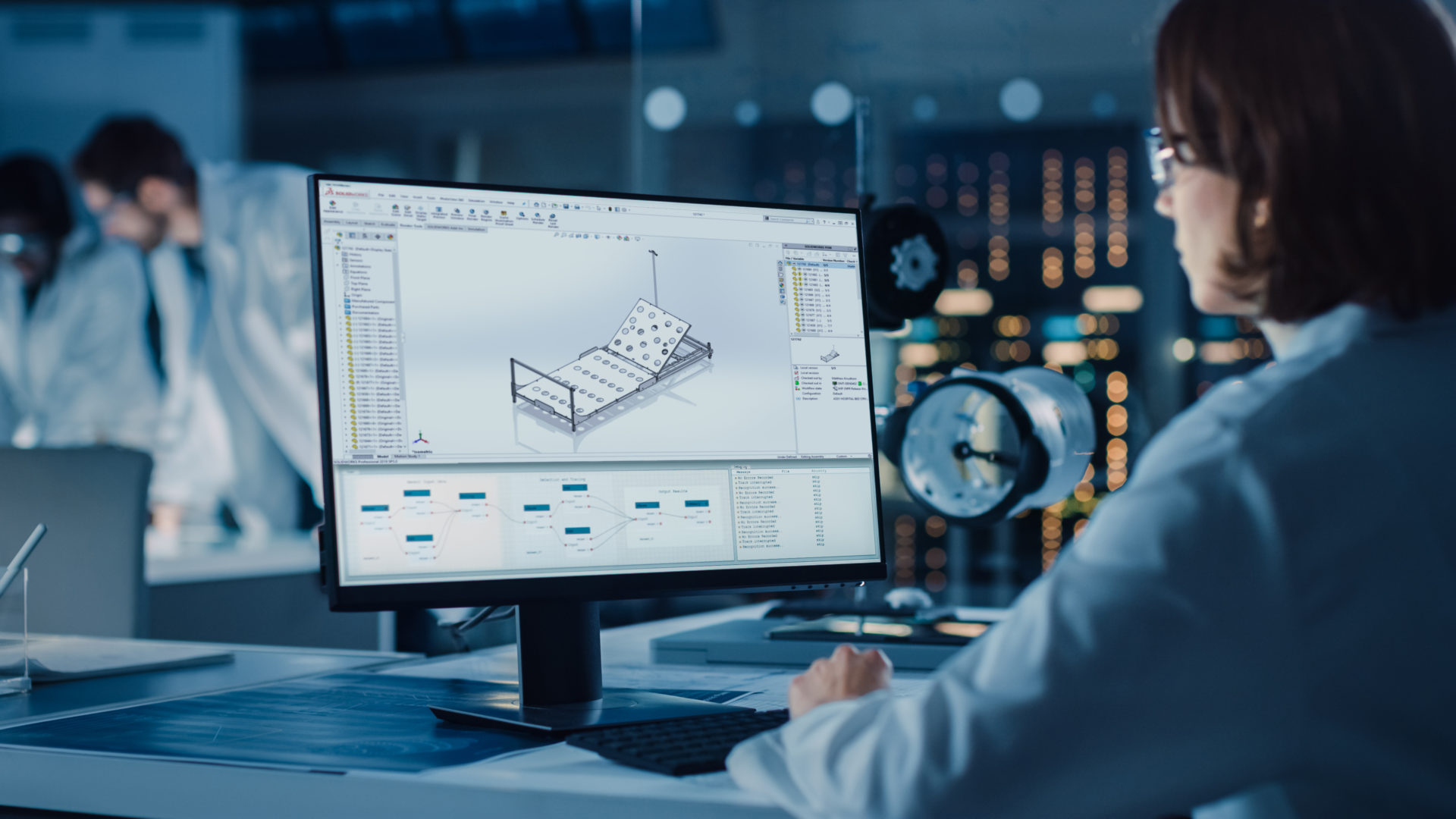

The company already had a large offering of medical beds; however, none of these options fit this unique situation. The typical 12-week lead time would be too long, and these hospitals needed a basic, economical version compared to the current higher-priced options. To solve this, a team from the medical device company designed a new bed in a week’s time and began looking to source it.

The Right Capabilities

Their immediate goal was to create 25,000 beds and get them distributed out to the field as fast as possible. A principle engineer stated that finding enough manufacturers to get the job done was difficult, and he utilized all the available capacity in Michigan and Indiana for laser cutting.

“From day one it was simply a ‘go figure out how to get this done’ project. For us, it was a delivery exercise to see how fast we could get the beds and turn them around.”

“One of the great benefits we had with OMT-Veyhl was their ability to do everything we needed right in-house – from tube lasers, to sheet metal, to powder coat. Other suppliers turned into a logistical nightmare.”

“One of the great benefits we had with OMT-Veyhl was their ability to do everything we needed right in-house—from tube lasers, to sheet metal, to powder coat. Other suppliers turned into a logistical nightmare.”

Making It Happen For You

While navigating such a unique and speed-to-market project, communication between a manufacturer and their customer is vital to success.

While navigating such a unique and speed-to-market project, communication between a manufacturer and their customer is vital to success.

“Because of the high volume, we went directly to the mills to buy the raw materials that we would provide our suppliers with. This ended up being one of the biggest challenges, but OMT-Veyhl made it easy. They had great communication on when they were getting low and needed more steel. It seems like a really well-run organization.”

Overall, the medical device company used 19 suppliers, with OMT-Veyhl outputting 756 beds per week. The final bed was the perfect solution that was readily available to serve those on the front lines of the COVID-19 crisis – ranging from triage centers and pop-up areas of care, to the emergency department, and all in-patient hospital general departments.