The Magic that Creates Our Products Isn’t the Point. The Results Are.

We design and manufacture the highest quality fixed and adjustable-height table and desk bases available in the office furniture industry today.

Every product we manufacture is made to the highest quality standards, incorporating premium materials, LEAN manufacturing processes, and the latest innovations in automated manufacturing equipment. Our lead times and quality standards are the envy of the industry.

As an original equipment manufacturer (OEM) supplier, we partner with you to develop innovative products made right here in the US. Our goal is to consistently reflect the quality, ergonomic standards and design style that your brand depends on.

It’s time to discover what the right manufacturing partner can empower you to achieve.

Innovation, Research & Development

Our product development process is designed to shrink the gap between prototype and final manufactured process. We use production equipment for every prototype, allowing us to document and replicate our processes. We rigorously test our prototypes and then complete a full test run to validate every part and step in the process to reduce cost and ensure quality.

Now your product is ready for efficient, low-cost, high-quality production.

Quality & Testing

Quality begins with design and testing. We engineer every assembly we make to withstand the forces of the modern workplace. We then verify that our products are performing as expected in our Onsite Test Labs which replicate every major test required under BIFMA and UL standards. Once we’re confident in the quality of our prototypes, we send them to third-party labs for external testing and verification.

Quality control continues throughout the manufacturing process. Virtually every step of production that can be automated is. With precision-driven equipment and a wide variety of fixtures that ensure precise part placement, our production process creates parts to very high tolerances. Completed parts have to satisfy go/no-go gauges, catching errors before assembly. After assembly, computer-assisted quality control helps the right parts are included in every package.

It’s quality you have to experience for yourself to appreciate. Give us a call and schedule a tour to see the OMT-Veyhl difference for yourself.

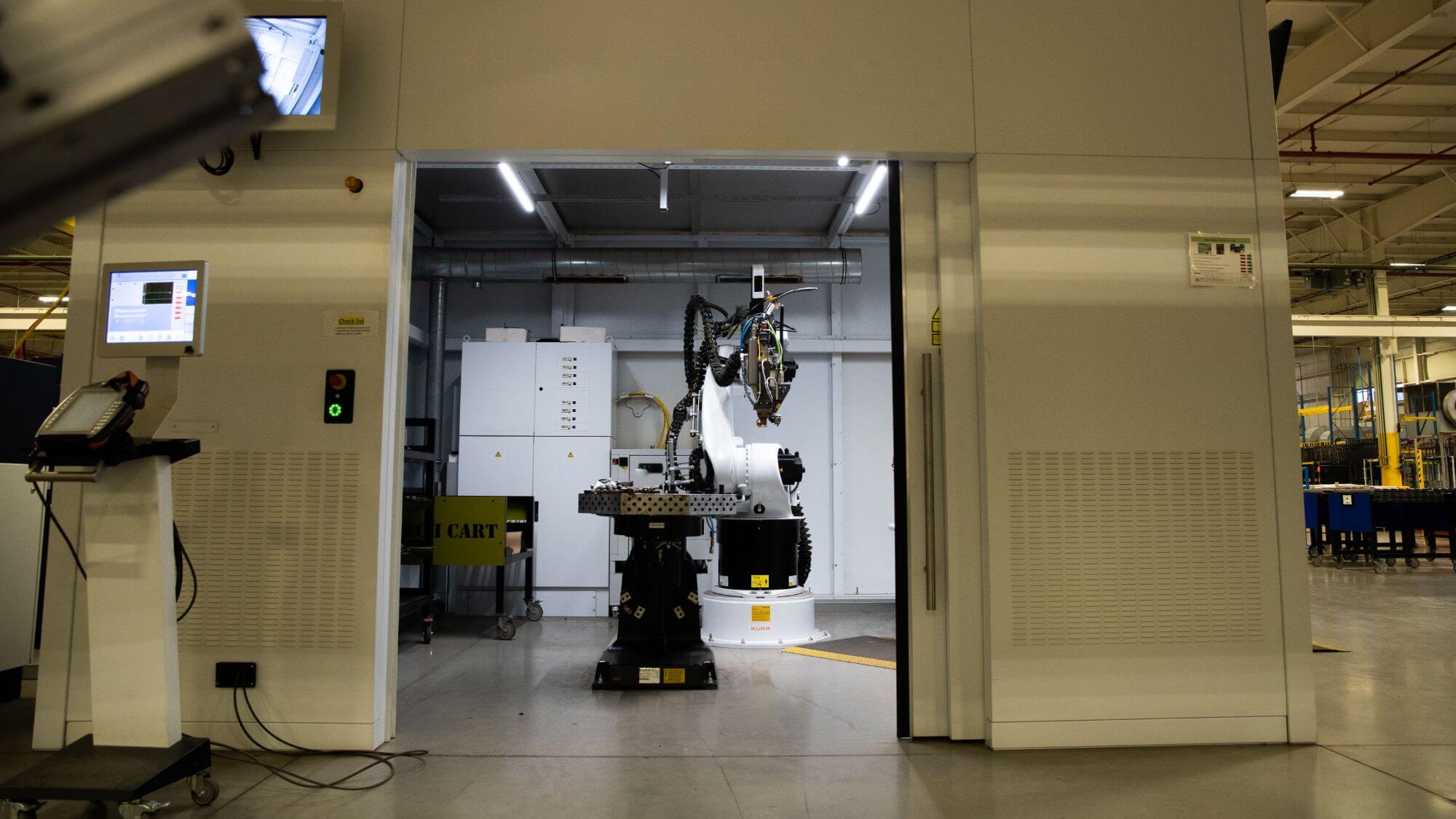

Manufacturing Technology

Computer-driven laser-cutters cut parts quickly to very high tolerances. Our brake presses provide for rapid bending and forming. Robotic laser welding rapidly creates assemblies with a very high degree of fit and finish, less material waste, and little to no burn through. It all contributes to the highest standards of manufacturing quality and efficiency.

Our plant operates two assembly line departments: one for high-volume height-adjustable tables and one for fixed-height tables. Each team member is cross-trained in efficiency, consistency, and quality. Your product is assembled to exacting standards each and every time.

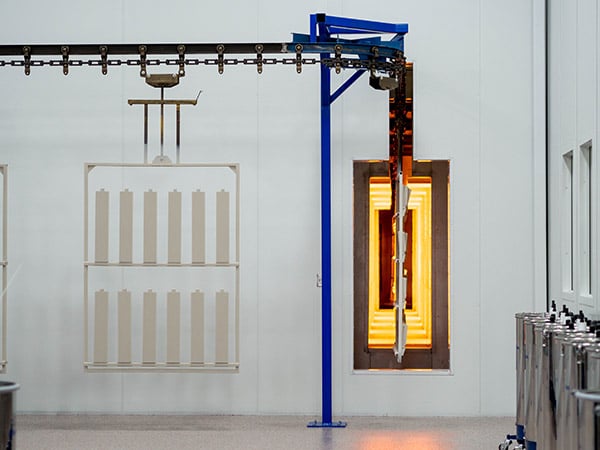

Powder Coating

At OMT-Veyhl, our favorite color is yours. With more than 150 standard colors and the ability to customize a finish to suit your requirements, we offer color options that are unsurpassed in the industry. See our Color Quick Reference to get started.

Two separate powder coating lines are available to accommodate your needs for everything from small-run customization to large-order production.

The newest of our two finishing is custom-designed and fully automated, making it the only one of its kind in the world. This powder coat line was engineered for efficiency and speed, enabling single-rack changeovers. Its waste reduction technology also allows us to operate with minimal overspray.

Our manual powder coat line is run by skilled technicians who can change colors in 30 seconds on average and as many as 180 color changes in a day.