Case Study: Pairing Custom Design With Tight Turnarounds

Client

Leading Michigan furniture manufacturer

Problem

The customer’s current benching solution wasn’t perceived as sturdy enough and needed additional wire management. Something more robust was needed on a very tight timeline.

Solution

OMT-Veyhl provided a customized desking solution, engineering and delivering a mockup within 10 days.

Summary

When a manufacturer is approached for a custom furniture solution, timeline often can be one of the biggest hurdles. So when the timeline is condensed to just a few weeks, attention to detail and a keen market understanding are mission-critical skill sets. Learn how a leading Michigan-based contract furniture company partnered with OMT-Veyhl to transition from a napkin sketch to a delivered mock-up in just ten days.

Introduction

With more than 60 years of experience serving the contract interiors industry, a leading Michigan furniture manufacturer was a natural choice when a New York–based financial data and media company set out on a mission to maximize its floor space while working to eliminate the use of cubicles. After careful consideration and consultation with the client, the manufacturer originally considered a benching solution already in its arsenal. The product was at the price point the firm wanted, but there were a few concerns.

For starters, the client specifically requested a solution that featured a cable tray with power, something current models didn’t have. What’s more, it also required a height-adjustable desk that offered the same rigidity in the seated position as it did in the standing one. Yet when at full extension, the desk didn’t meet the expectations of the client. Because many workers utilized multiple large monitors on their desks, the combination of these two factors led to the realization that the existing solution didn’t meet all the firm’s goals. The manufacturer was back to the drawing board.

Experience Speaks For Itself

Having previously worked with OMT-Veyhl on custom-designed pieces, the manufacturer turned to the trusted contact known for getting the job done. A tailored solutions product specialist and project engineer from the manufacturer recalled the initial consultation vividly. “When working with OMT-Veyhl, each custom request is nothing more than a working lunch with a napkin sketch and a few questions to understand what we want. OMT-Veyhl just gets it. They know the industry in and out and have the capabilities to design and develop custom solutions to address the needs we’re seeing in the market today.”

The engineer added that the traditional new-product development cycle for his company was 8 to 18 months. The only problem? The client wanted samples delivered to the New York showroom in three weeks. The clock was ticking, and there was no room for error.

Designing an Innovative Solution

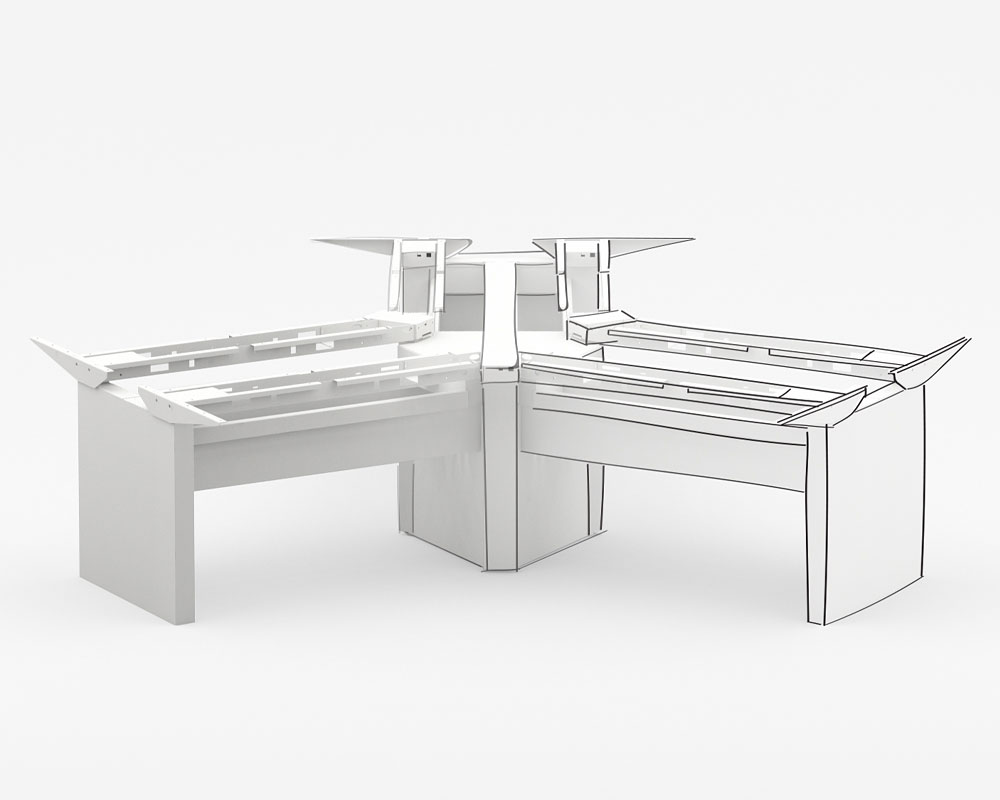

OMT-Veyhl responded to the request with a benching system featuring a rectangular back-to- back benching solution. By integrating a unique cable management trough to support the client’s demand for power and data, OMT-Veyhl’s design accomplished both the goal of incorporating power into the workstation while also addressing the perceived wobbliness of the original design. And through the installation of additional metal cladding that helped conceal wires, the design was just as sleek as it was practical. All of this was accomplished with a prototype that was easy to assemble correctly the first time around—a benefit that proved to be one of the winning features of the manufacturer’s model. All in all, from napkin sketch to CAD model to manufactured prototype, the process took ten days to complete and was delivered to the New York testing ground, where the project was later awarded. While the first project was just under 1,300 units, the product’s success has snowballed into several additional orders for the manufacturer, which continues to work with OMT-Veyhl on new tweaks to power design and base construction to further meet the needs of the evolving market and its respective clients.

OMT-Veyhl responded to the request with a benching system featuring a rectangular back-to- back benching solution. By integrating a unique cable management trough to support the client’s demand for power and data, OMT-Veyhl’s design accomplished both the goal of incorporating power into the workstation while also addressing the perceived wobbliness of the original design. And through the installation of additional metal cladding that helped conceal wires, the design was just as sleek as it was practical. All of this was accomplished with a prototype that was easy to assemble correctly the first time around—a benefit that proved to be one of the winning features of the manufacturer’s model. All in all, from napkin sketch to CAD model to manufactured prototype, the process took ten days to complete and was delivered to the New York testing ground, where the project was later awarded. While the first project was just under 1,300 units, the product’s success has snowballed into several additional orders for the manufacturer, which continues to work with OMT-Veyhl on new tweaks to power design and base construction to further meet the needs of the evolving market and its respective clients.

Benefits of a Cohesive Partnership

According to the engineer, the benefits of working with OMT-Veyhl were twofold. “The ability for OMT-Veyhl to complete this project in our extremely tight turnaround speaks to its ability to allocate resources to get the job done.”

But beyond the ability to meet a seemingly unrealistic timeline, OMT-Veyhl’s true worth according to the manufacturer, lies in its ability to understand the complexity of the problems. “The value is having a partner with the vision needed to create customer successes. People want to design spaces that fit their culture—you can’t buy that out of a catalog. Instead, OMT-Veyhl works as a partner with us on a multitude of projects, helping us tangibly take concepts to reality through a strong understanding of customer vision.”